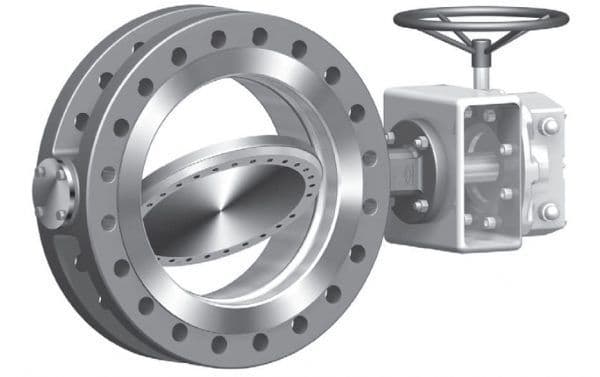

Everything to Know About Triple Offset Butterfly Valves

Butterfly valves have long been a staple in the world of industrial flow control, and among them, the triple offset butterfly valve stands as a testament to innovation and precision engineering. In this comprehensive guide, we will delve deep into the realm of triple offset butterfly valves, uncovering the secrets behind their design, their applications, and the undeniable advantages they bring to a multitude of industries.

What is a Triple Offset Butterfly Valve?

Triple offset butterfly valves are a class of industrial valves renowned for their exceptional performance and versatility. They are aptly named due to their unique design, which features three distinct offsets that set them apart from traditional butterfly valves.

Triple Offset Sealing: The first offset is in the shape of the sealing geometry. Unlike traditional butterfly valves with a centered shaft, triple offset butterfly valves have an eccentrically mounted shaft. This offset allows the sealing element to make contact at different points, minimizing wear and ensuring a tight seal.

Triple Offset Shaft: The second offset is the shaft geometry itself. It is not only eccentrically placed but also inclined at an angle. This design eliminates friction during operation, resulting in less wear and tear, reduced torque requirements, and extended valve life.

Triple Offset Rotation: The third offset pertains to the rotation of the disc. Traditional butterfly valves open and close with a quarter-turn motion. Triple offset butterfly valves, however, rotate the disc through a cone-like path. This geometry allows for precise control of flow, minimizing turbulence and pressure drop.

Applications of Triple Offset Butterfly Valves

Triple offset butterfly valves find applications in a wide array of industries where reliable, tight shut-off and control of fluid flows are critical. Here are some notable applications:

1. Oil and Gas Industry

In the oil and gas sector, these valves are used for high-pressure and high-temperature applications, such as pipelines, refineries, and offshore platforms. Their ability to withstand harsh conditions and maintain a tight seal makes them indispensable.

2. Chemical Industry

Triple offset butterfly valves are highly corrosion-resistant, making them ideal for handling corrosive chemicals. They are used in chemical manufacturing plants to regulate the flow of various substances.

3. Water Treatment

Water treatment facilities rely on these valves for their precise control capabilities. They help in managing the flow of water and chemicals, ensuring the efficient treatment of drinking water and wastewater.

4. Power Generation

Power plants, both conventional and nuclear, use triple offset butterfly valves in critical systems. Their durability and reliability are essential for maintaining operational safety.

5. Pulp and Paper Industry

In the pulp and paper industry, these valves are employed for handling abrasive materials and high-consistency pulps. Their resistance to wear and tear makes them valuable assets in this sector.

6. Aerospace and Defense

Triple offset butterfly valves play a vital role in aerospace applications, including rocket propulsion systems and aircraft fuel management. Their precision and reliability are paramount in these critical areas.

Advantages of Triple Offset Butterfly Valves

1. Zero Leakage

One of the most significant advantages of triple offset butterfly valves is their ability to achieve a bubble-tight seal. The triple offset design ensures that the sealing element only contacts the seat during the final moments of closure, minimizing wear and preventing leakage.

2. Low Torque Requirement

Thanks to their eccentric shaft design, these valves require significantly less torque to operate compared to conventional butterfly valves. This feature translates to lower energy consumption and reduced wear on valve actuators.

3. High-Performance Materials

Triple offset butterfly valves are available in a wide range of materials, including stainless steel, carbon steel, and exotic alloys. This versatility allows them to handle diverse applications and corrosive environments effectively.

4. Precise Control

The cone-like rotation of the disc provides precise control over fluid flow. This characteristic makes triple offset butterfly valves suitable for throttling applications, where accurate flow regulation is crucial.

5. Durability and Longevity

Their robust construction and reduced frictional forces contribute to an extended service life, reducing maintenance and replacement costs.

The Future of Flow Control: Embracing Triple Offset Butterfly Valves

In an ever-evolving world where precision and sustainability are paramount, the triple offset butterfly valve has emerged as a beacon of trust and excitement. Its unique design, characterized by three offsets, heralds a new era in flow control technology.

What sets these valves apart is their unwavering commitment to zero leakage and tight shut-off, attributes that are vital in critical industries such as oil and gas, power generation, and aerospace. With their ability to withstand extreme pressures and temperatures, they have become the go-to choice for safeguarding crucial processes.

Furthermore, the reduced torque requirements of triple offset butterfly valves translate into lower energy consumption, which not only aligns with sustainability goals but also reduces operational costs. This, coupled with their extended service life, contributes to a more environmentally conscious and economically viable solution.

Conclusion

In the realm of industrial valves, the triple offset butterfly valve stands tall as a symbol of innovation and excellence. Its unique design, which incorporates three offsets, sets it apart from traditional butterfly valves and imparts remarkable advantages.

From the oil and gas industry to water treatment facilities, aerospace applications to power generation, triple offset butterfly valves have found their place in critical systems where reliability, precise control, and zero leakage are non-negotiable.

In a world where fluid flow management is paramount, these valves offer an exciting combination of performance, durability, and efficiency. Their ability to deliver tight shut-off and precise control make them indispensable tools across various industries.

So, whether you're in search of a valve that can handle the harshest of environments or seeking precise control over fluid flow, the triple offset butterfly valve is a beacon of trust and excitement in the world of industrial valves. Its enduring legacy of performance and innovation continues to shape the industries it serves, making it a true engineering marvel.

Make the smart choice. Embrace the triple offset butterfly valve and unlock a world of possibilities in fluid flow management. Trust in its precision, reliability, and durability, and experience the future of industrial valve technology.

Appreciate the creator