A Comprehensive Guide to Steel Ducting Systems

Steel ductwork is a critical component of any building's infrastructure. It provides a flexible, durable, and cost-effective method for connecting ductwork systems.

While steel ducting is not unique to this purpose, it has become an increasingly common component of modern building construction due to its durability, flexibility, and low cost. It is also becoming increasingly popular in commercial buildings because it can be used as an alternative to aluminium ducting in areas where it may not be possible to use aluminium due to special requirements, such as corrosive environments or high temperatures.

In this blog, the various types of steel ductwork will be discussed as well as how they can be used in different types of industries and what are some benefits associated with it.

About Galvanised Steel Ducting

Hot-dip galvanising, in which steel is coated with a thin zinc layer, is commonly used in producing galvanised steel ductwork. The steel goes through a bath of zinc heated to around 860 degrees Fahrenheit (460 degrees Celsius). Exposed to air, pure zinc becomes zinc oxide, which in turn forms zinc carbonate, a dark grey, somewhat robust substance that resists further corrosion in many conditions, safeguarding the steel underneath. The crystalline patterning on the surface of galvanised steel is a telltale sign that it has been treated to prevent rust. This makes it an ideal material for use in ducting.

Hot-dip galvanising fortifies zinc and steel using a variety of iron-zinc alloys, making for a cost-effective and adaptable material for ducting and duct components. The resultant coated steel is functionally equivalent to uncoated steel.

Galvanised steel can withstand temperatures up to 392 degrees Fahrenheit (200 degrees Celsius). When used at higher temperatures, the zinc may peel away from the intermetallic layer. Ducting made of galvanised steel is often used for dust collection.

Industries

Construction

Welding

Cement, lead, or wood production

Applications

Outdoor applications

Dust extraction

Fume extraction

Benefits

There are several advantages to using galvanised steel ductwork:

Galvanised steel duct's heavy-duty coating is a unique metallic structure designed to withstand wear and tear from mechanical stress.

For the most part, galvanised ductwork is the industry standard since it is the most cost-effective over time and requires the least amount of upkeep.

Compared to other materials, galvanized steel ductwork's smooth surface aids airflow and helps prevent the formation of mildew and fungus.

With proper maintenance, galvanised coatings can survive for over 25 years in urban and coastal locations and up to 50 years in rural areas.

When it comes to corrosion, rust, water, and moisture damage, even in inaccessible regions, the galvanized steel ductwork will always have your back.

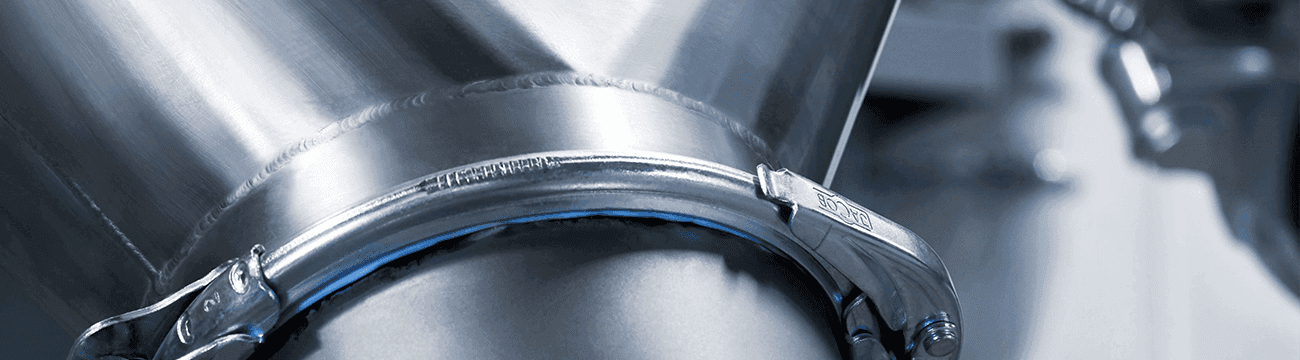

About Stainless Steel Ducting

Experts in a wide variety of fields rely on stainless steel ducting solutions. They are one of the most efficient choices available, despite their greater upfront cost.

Ventilation systems installed in hot or humid climates benefit greatly from the use of stainless steel ducting materials. When the air contains components that might be harmful to more common materials like galvanised steel ducting, stainless steel ventilation ducting becomes a desirable alternative. When working in hostile situations where corrosion is expected, HVAC specialists and engineers often choose stainless steel. This is because stainless steel has a quality that makes it resistant to corrosion.

Industries

Food processing

Laboratory

Pharmaceutical

Chemical manufacturing

Swimming pool facilities

Applications

Indoor and outdoor use

Seawater applications

Kitchen use

Dust extraction

Fume extraction

HVAC Systems

Benefits

There are several advantages associated with using stainless steel ducts in HVAC systems and other applications. Some of these include:

Durable

Stainless steel is corrosion-resistant, so it will not rust, stain or corrode. This makes it ideal for corrosive environments such as chemical processing plants and petroleum refineries. In addition to being corrosion resistant, stainless steel ducting has high tensile strength and impact resistance which help prevent damage from mishandling during installation.

Lighter Weight

Stainless steel ducts are lighter than other materials like aluminum or galvanized steel. This means they require less support when installed which can significantly reduce costs related to installation labor. Stainless steel ducts can also be used vertically or horizontally without requiring additional supports which further reduces installation costs.

Good Thermal Insulation Properties

Stainless steel has excellent thermal insulation properties that make it suitable for use in applications where heat loss prevention is critical such as industrial ovens or furnaces.

Simple Fabrication

Aluminum's malleability makes it a challenge to work with in manufacturing. The fact that it isn't steel makes it exceptionally challenging to weld. As a result, aluminum ducting often has a higher final cost than stainless steel ducting.

Eco-Friendly

Ducts made of stainless steel, which can be recycled indefinitely, are extremely eco-friendly. Not only does steel not rust or mildew readily, but it can also withstand high levels of humidity and condensation without any trouble. These ducts are often used because they remove moisture from the air, preventing the formation of mildew that can occur when air conditioning ducts are used. Once the ducts have served their purpose, they may be recycled so that they are never dumped in a landfill.

Takeaway

Steel ducting systems are a great way to improve the efficiency and safety of your industrial or commercial building. They can be used for connecting ductwork in any type of building, including warehouses, factories, and storage facilities.

This guide has provided you with all of the information you need to choose the right type of steel ducting system for your needs.

Appreciate the creator